| In addition to the data crankshaft and moving masses, by accessing

on the design area of the software Crankshaft Balance Design you must

enter some data of the engine, the transmission and the vehicle. Thanks to these data in fact

the software performs a global calculation to see how choices of balance and inertia of the crankshaft are combined with the

characteristics of engine and vehicle, allowing you to find those that

provide the best performance. |

|

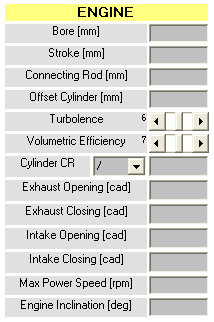

| Regarding the engine you must enter the main features, the compression ratio of cylinder and crankcase, and the timing.

Moreover you can manage some parameters related to the

engine efficiency (turbolence and

volumetric efficiency) in order to fully define the

engine performance. With this data the software

Crankshaft Balance Design

can calculate the pressures that there are in the cylinder and determine the loads

that together with the inertia forces influencing

friction, stress and vibration on the frame. |

|

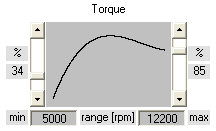

In addition to these data you must enter the curve

engine torque, so the software Crankshaft

Balance Design will calculate

as the choices in terms of inertia of the crankshaft are translated in the performance that there are during acceleration and gear shift. |

|

|

|

|