|

|

|

|

|

|

|

click on the image

for the presentation |

Professional

Cam is the ideal and complete software for

engineering, team, tuner, etc. developing camshafts. In

fact the software allows, to design valve lift law, to calculate

cam profile for the main type of valve train system, to verify

the valve train system with the spring load calculus and also to

analyze the geometry of combustion chamber. |

|

|

|

|

|

|

|

Presentation

|

The camshaft is the

heart of the 4-stroke engine, and is therefore one of the components

on which we mainly act to improve engine performance.

Usually after that have been defined the new valve timing and the

maximum valve lift, two important steps must be overcome to create

new cams :

| calculation of the lift law

which must satisfy the dual purpose of maximizing the

volumetric efficiency and to guarantee the mechanical

reliability |

| calculation of the cam

profile which implements the lift law calculated in function

of the valve train system of the engine |

The software Professional Cam allows you to tackle these phases in

an easy and professional way.

|

LIFT LAW

The software Professional Cam offers the possibility to obtain

multiple lift laws, in this way it will be possible to satisfy the

different needs, performance, reliability, and feasibility of the

cam in function of the features of the valve train system.

Specifically, the software contains all the main lift laws that have

been developed over the years and which appear to be the most

suitable for the needs of the engines.

|

LIFT |

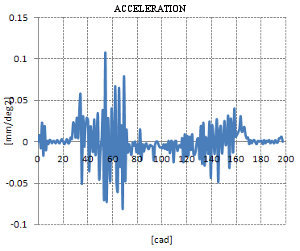

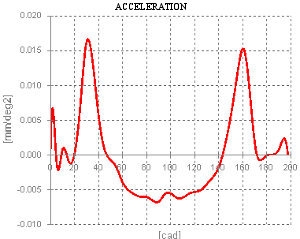

ACCELERATION |

|

|

| NT-Polydyne |

This type of lift law is based on particular "polydyne"

polynomials appropriately modified with a special algorithm

to optimally connect it to eventual ramps, hence the name

"NT-Polydyne". |

| NT-Spline |

This type of lift law is based on "splines"

appropriately designed to create laws that satisfy the needs

of engine valve train systems and which connect in an

optimal manner to eventual ramps, hence the name

"NT-Spline". |

| NT-Trigonometric |

This type of lift law is based on trigonometric laws

appropriately studied to create laws that satisfy the needs

of engine valve train systems, and modified with a special

algorithm to optimally connect to eventual ramps, hence the

name "NT-Trigonometric ”. |

| NT-Polynomial 8° |

This type of lift law is based on an 8° polynomial law

appropriately modified with a special algorithm to optimally

connect to any ramps, hence the name "NT-Polynomial 8°". |

| NT-Dudley |

This type of lift law is based on the particular

"polydyne" polynomials developed by Dudley appropriately

modified with a special algorithm to optimally connect to

eventual ramps, hence the name "NT-Dudley". |

For each of these laws it is possible to manage some parameters that

modify the level of aggressiveness of the law, furthermore these

laws can also have ramps to recover the valves clearance, and can

also have an asymmetric profile.

Into the software is also possible to import lift laws detected

experimentally, and thanks to a special filtering algorithm it is

possible to use them to obtain the cam profile.

| CALCULATION FROM

UNFILTERED DATA |

CALCULATION WITH NT FILTERED DATA |

|

|

In fact, the lift laws detected experimentally present various

measurement errors, which emerge when speed and acceleration are

calculated. Therefore, without adequate filtering and reprocessing

it would be impossible to reuse them to calculate the cam profile.

|

VALVE TRAIN

SYSTEM

The software Professional Cam Pro allows to calculate the cam

profile for all the main valve train system, from those at direct

attack, both with flat tappet, both with roller centered or offset,

to those with rocker arms or finger arms, until to the systems with

pushrods and rocker arms, both with flat tappet, both with roller

centered or offset.

In the version Basic of the software there are only the valve train

system with direct attack, both with flat tappet, both with roller

centered or offset

The insertion of the data in the software to define the features of

the valve train system has been designed to be as easy as possible,

in this way even without having the drawings of the valve train

system it is possible to collect the necessary data with simple

experimental measurements.

|

SYSTEM

DYNAMIC

By entering the weights of the elements of the valve train system

and the features of the springs, thanks to the software Professional

Cam it is possible to quickly check whether there are valve floating

conditions and evaluate the level of the Hertzian pressure acting on

the cams.

|

ENGINE

When you change the valve timing and the maximum valve lift one of

the problems that you may encounter is interference with the piston,

therefore in the software Professional Cam there is a module where

you can enter the main data of the cylinder head and of the piston,

for hemispherical and roof combustion chambers, and carry out a

simulation of the operation to have an initial assessment of the

situation.

|

In the

videos that follow you can see the different functionalities

described above in more detail.

The functions relating to the lift present in the video have been

updated in the latest edition of the software, for this reason you

can refer to what is shown in the presentation.

|

| |

| As you have

seen, the software Professional Cam is the ideal tool for developing

new cams, in fact it allows you to easily define your project,

satisfying at the best the different needs of performance,

reliability and feasibility. |

| |

Purchase |

|

|

|

|

NT-PROJECT - Ferrara (Italy)

- info@ntproject.com |

tutto il

materiale contenuto nel presente sito è coperto dalle leggi sul diritto d'autore ©

2005/19 |

|