|

|

|

|

|

|

|

click the image

for the presentation |

SET-UP Gear

to exploit at the maximum the potential of the motorbike engine is

necessary to use the best gear ratio. The choice

of front and rear sprockets depepnds from the features of the

track and from the weather and grip conditions that there

are, for this the choice isn't easy and should be found by trial,

but in the race w.e there isn't the time, moreover the

conditions change continuously,

so you go a little blindly.

The software SET-UP Gear

instead allows you to choose without fail before even to

go on the track the optimal final drive ratio of the motorbike in function of the track and of the conditions

that there are, so you'll can make the difference in each session of qualify and race. |

|

|

|

|

How it works?

|

To be able to find the gear ratio that allows you to get the

best performance on a given track, in the atmospheric and grip

conditions that there are, so far we have relied on the experience

accumulated in previous sessions on that track, or to the sensations

of the rider in the previous run, however, in a w.e of race the

weather and the track conditions change continuously, so the

information passed often are of little use, for this reason

NT-Project has developed the software SET-UP Gear

that allows to simulate the performance of the motorbike on the

different tracks in function of the characteristics of the chassis,

the engine, the tires, and the final drive ratio used, obviously

depending on the weather and grip conditions, in this way, you can quickly find the sprockets to use

to get the best performance and to make the best choice first

still to go on the track.

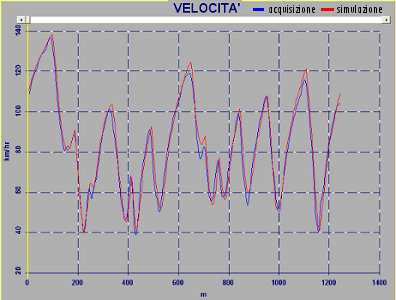

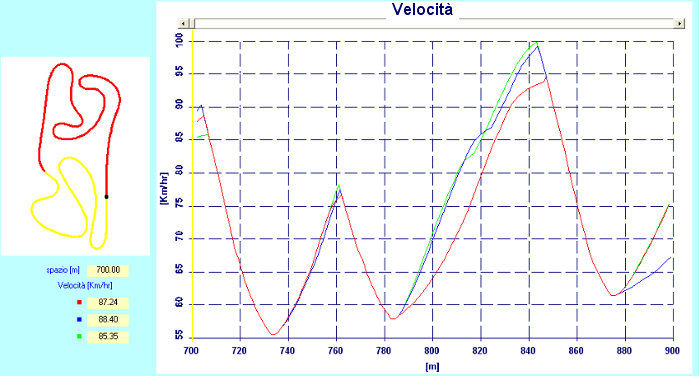

| As you can see from the following graph the performance simulated by

the software has a remarkable precision compared to the real drive

(the only differences in some points are related to a better

exploitation of the grip by the virtual rider compared to

the real one),

therefore the indications on the optimal transmission ratio to use are

fully realistic. |

|

The software SET-UP Gear as well as helping you in choosing the final drive ratio,

in motorbike engines with gearbox, it also helps you to to find the engine speed of upshift and downshift to exploit at the best your engine, moreover in the motorbike where you can manage the distribution of

braking between front and rear, tells you which is the optimal setting of the braking distributor.

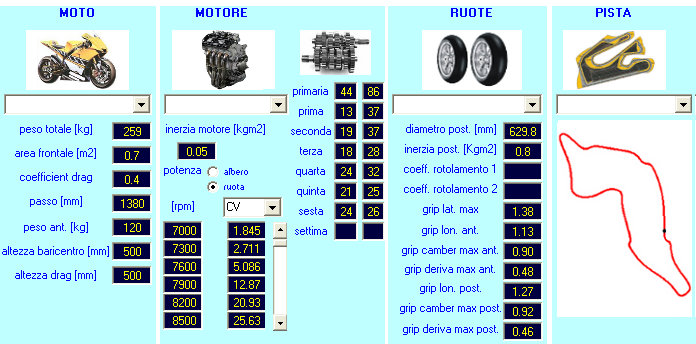

To use the software is very easy, in fact you will have to simply

choose in your software, your motorbike category, the engine that you

use, the tires, and the track where you want to calculate the

optimal final drive ratio.

The data necessary are very easy to find, in fact :

|

for the motorbike is necessary to carry out some measures to

determine the wheelbase and the balance, while for what

concerns the drag resistance can be used sample data fully

adequate for most of the motorbikes. |

|

for the engine the power curve must be entered, this can be

detected at the dyno, or, if you have a data acquisition

system on the motorbike, it can be calculated directly by

the software, importing the data of a session. In addition

to these data, the gearbox gear pair ratios must be entered. |

|

for the wheels the dimensions and the grip characteristics

must be inserted, for these you can use example data for the

most used tires, or, if you have a data acquisition system

on the motorbike, they can be calculated directly by the

software, importing the data of a session. |

|

for the track, since the track line significantly determines

the result, it is advisable to use the data acquired on the

track of interest, and calculate the trajectory directly

with the software. |

|

|

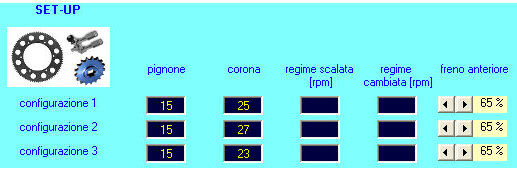

At this point inserting the weather conditions and the level

of grip, you can simulate 3 configurations of the front and

rear sprockets to find the one that allows you to get the

best lap time. |

|

|

|

Results |

OPTIMAL MOTORBIKE FINAL DRIVE RATIO CALCULATION

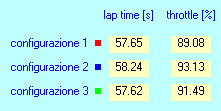

In a few seconds the software SET-UP Gear shows you the results of the simulated performance in the different configurations.

|

The most important data is the lap time, that allows you

to find immediately the best configuration, in the case of

the example the final drive ratio used in the configuration

3 has given the best lap.

In addition to the lap time, however, is also shown how the

throttle should be choked depending on the configuration

chosen, this is important to understand if the final drive

ratio chosen tends to generate a more consistent slide that

can lead to an early wear of the tires. In the case shown,

configuration 1 needs more throttle cut, while the 2 allows

to exploit the gearbox differently and to be able to use the

throttle more easily, but at the expense of the lap

performance, so even under this aspect the configuration 3

is the best compromise. |

The software in addition to the lap time, and to the average thottle

cut, shows also the graphs of the speed, of the engine speed, and,

in the engine with gearbox, of the gear shift used, so will be possible

also analyze in the detail how in the differents point of the track,

the differents final drive ratio influence the performance.

|

|

Others features

|

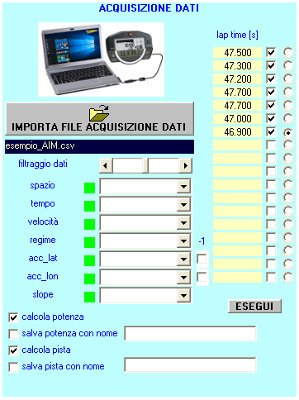

POWER CURVE and TRACK LINE CALCULATION from ACQUISITION DATA

|

As said initially the software SET-UP Gear allows to calculate

directly from the data acquired from your acquisition,

the power curve of your engine, the tyres grip, and the track line

carried out by your rider, in this way the calculation of the

better transmission ratio will be even more accurate for your case

specific. |

|

|

Others Results |

OPTIMAL GEAR UPSHIFT and GEAR DOWNSHIFT CALCULATION

In addition to the possibility to simulate the performance changing the

final drive ratio the software allows to find which is the

operating range to exploit at the best the motorbike engine, in fact is

possible to keep fix the final drive ratio and to modify the upshift and downshift engine speed to see which are the optimals to obtain the best lap time.

In the example shown, you can see that the utilization ranges chosen in the

configurations 2 and 3 give to a very similar performance, but

in the 2, against a slight advantage, is necessary to cut much more the throttle, so maybe you can take advantage to use the

engine in this way in qualify, but in the race is better to stay on

a different utilization to preserve better the tires. Thanks to the software

SET-UP Gear, is therefore easy to suggest to the rider in which operating range

to use the engine to get the best performance, and to do the

best choices also to take account of the tires duration.

OPTIMAL MOTORBIKE BRAKING DISTRIBUTION CALCULATION

For the motorbike where is possible to manage the braking with the

distributor, an other important calculation that performs the software SET-UP Gear

is that to find the brake distributor setup to obtain the most effective braking in function of the track and of the grip condition.

In the example shown you can see that on the track under

examination, to distribute the braking more on the front gives an

improvement until to 60%, after tends to get worse. The optimal

value obviously changes in function of the features of the track,

and of the grip conditions, and since that are little differences

often for the rider isn't easy to understand on which direction

move the distribution to improve, instead thanks to the software

SET-UP Gear you can find the best setup of the braking distribution

fastly and with precision for each track and on every condition.

How you've seen the software SET-UP Gear allows you to improve the performance

finding the optimal setup to exploit at the best your motorbike engine (optimal final drive ratio and optimal engine operating range), and to

the most effective braking.

|

Purchase |

|

|

|

|

NT-PROJECT - Ferrara (Italy)

- info@ntproject.com |

tutto il

materiale contenuto nel presente sito è coperto dalle leggi sul diritto d'autore ©

2005/19 |

|