|

|

|

|

|

|

|

click on image

for the presentation |

Crankshaft Design

is a software developed to meet the needs of many manufacturers and tuners in the develops and optimization of the

crankshaft. This software is of essential help to identify the best solutions of balance and inertia for

each specific engine and every specific need, in order to

optimize performance, driveability and reliability. |

|

|

|

|

|

|

Features

|

|

The crankshaft as well as a structural point of view must also be studied for two fundamental aspects, the balancing of the forces generated by the movement of the reciprocating masses (piston, piston rings, piston pin and

small end of the connecting rod) and those rotating (big

end of the connecting rod, the crank pin), and also by the inertia that the crankshaft is able to offer.

In a single-cylinder engine, unless you introduce counter-rotating shafts, balancing can be only partial, and how to choose this partial balancing has always been the subject of discussion on what might be the best, in fact there isn't a better solution in absolute, but the optimum should be chosen according to the characteristics of the engine and of the vehicle for which the engine is employed. |

|

|

Same goes for what concerns the crankshaft inertia, lighter, heavier, holes, no holes, are questions that recur over time,

at which isn't possible to give an answer because also for this aspect the best solution depends on the characteristics of the engine and its use.

In view of this, in practice, it makek the initial choices and then on the basis of tests and repeated attempts are made any changes, this process is long and laborious and often do not know if the solution found is really the best.

|

The software Crankshaft Balance Design may appraise in advance the technical effects that the choices

of balance and inertia give in terms of performance and reliability in relation to the characteristics of the engine and

of the vehicle on which it is applied, allowing you to quickly find the optimal solution.

The software is structured in four sections that allow to analyze, to

calculate, and to develop, the crankshaft in the best way.

| CRANKSHAFT ANALYSIS |

In this section the software

calculates the main features of the crankshaft that

you've, or that you want develop, in fact calculates quickly

WEIGHT -

BALANCE - INERTIA of the crankshaft. |

| CRANKSHAFT DESIGN |

In this section the software calculates DIMENSION and

POSITION of the COUNTERWEIGHTS, or of eventuals HOLES,

to have a determined crankshaft balance, showing in the

meantime how are modified inertia and weight. |

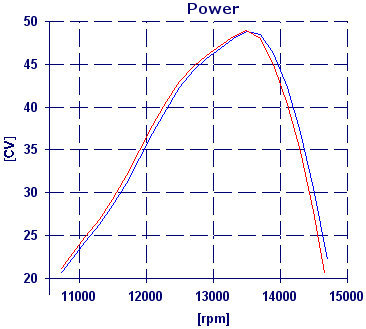

| ENGINE PERFORMANCE CALCULATION |

In this section the software calculates how changes the POWER CURVE of the engine in function of

the choices of

BALANCE and INERTIA that you've made on the

crankshaft. |

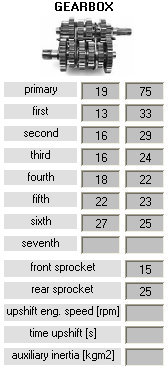

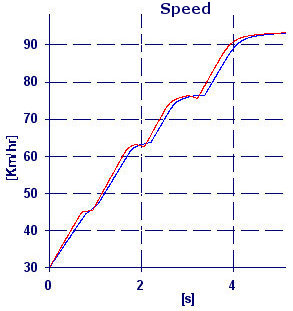

| VEHICLE PERFORMANCE CALCULATION |

This section avalaible in the version PRO of the

software allows to calculate the VEHICLE PERFORMANCE

keeping in account how the features of the crankshaft

influence the engine power, and the behavior in the gear shift phase. |

Below we will show in detail how the software works in the different

areas.

| CRANKSHAFT ANALYSIS |

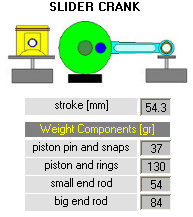

The software allows to calculate the main

features of the crankshaft in a simple manner.

In fact is sufficient to enter the informations of the slider crank (stroke,

and weights of the parts), and some data that allow to

define the crankshaft. In this regard the software offers different data entry opportunities to

meet all the needs. |

|

|

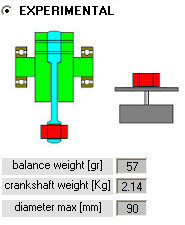

If you've made the classic experimental

test to calculate the balance, you can enter in the software

the value of the weight balance found, and the software in

function of the slider crank weights will calculate quickly

the BALANCE of your crankshaft. Moreover if

you measure the WEIGHT and the maximum diameter

of the crankshaft, the

software will calculate an estimate of the INERTIA of the crankshaft itself. |

|

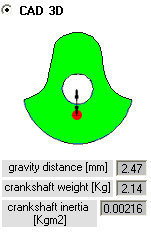

If you've the three-dimensional drawing of the crankshaft, from

your CAD 3D you can easily take over the gravity position, and the WEIGHT

of the crankshaft, thanks at these data the software will

calculate quickly the BALANCE of your

crankshaft in function of the slider crank weights. |

|

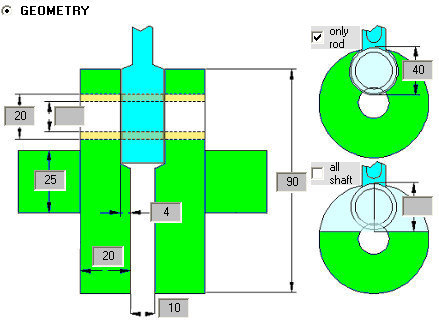

If instead your crankshaft has a classic full circle shape, or

you want develop a crankshaft of this type, the software thanks

the main dimensions will calculate automatically WEIGHT,

BALANCE and INERTIA of your crankshaft. |

|

If in the crankshaft are already presents counterweights, or holes,

in the software is possible easily to enter their

characteristics in order to take into account in the

calculations and to see how they affect WEIGHT, BALANCE and

INERTIA. |

|

|

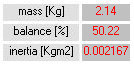

After to have entered the crankshaft data in the modality

that you prefer, and the features of the slider crank, the

software Crankshaft Design calculates WEIGHT, BALANCE, and INERTIA

of the crankshaft, both taking into account of the

counterweights and of the holes, both excluding them, in

this way it will be easy to understand too

the characteristics of the initial geometry of the crankshaft, and to evaluate the possibility of modifications. |

|

|

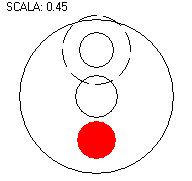

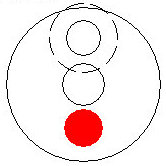

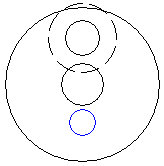

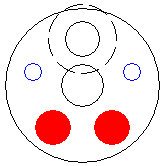

In addition to the calculations, the software draws

the geometry of the crankshaft that you entered,

allowing you to assess whether the data is correct and where there

is space for any modifications improvements. |

|

| CRANKSHAFT DESIGN |

|

If you want modify an existent crankshaft, or you want study

a new crankshaft, after the analysis phase which allows to

have a complete picture of the situation, the

software Crankshaft Design allows to study easily the

interventions to be carried out on the crankshaft to obtain

BALANCE and INERTIA that you want. |

The software allows in fact to calculate automatically

position and characteristics of the counterweights that are

necessary to achieve a determined balance.

|

|

|

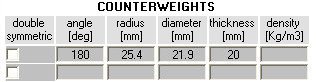

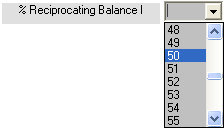

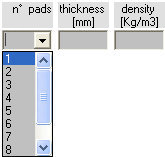

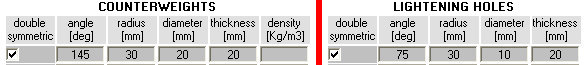

| For first you must

choose the percentage of balance that you want

obtain. |

In addition you can

indicate the number of counterweights that you want

use, the thickness of the counterweight, and the

material (density) |

Finally you can

choose if the position of the counterweights must

generate the minimum, or the maximum, inertia. |

|

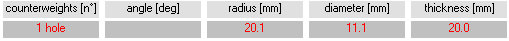

| At the end of the

calculation the software provides you all the informations of the counterweights that

you should use: |

|

|

|

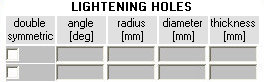

It also shows you how change the characteristics of

the crankshaft for the application of the

counterweights, and the relative drawing in scale: |

|

|

| This section of the software Crankshaft Design

can be used both to calculate the counterweights

of a crankshaft that has never been balanced. |

|

| Both to modify the balance of a crankshaft which has a different balance from

what we want. |

|

|

| If for example you've

already a crankshaft with a balance of 50% and you

want to go at a balance of 40%, the software will calculate

dimensions and position of the hole to make on the crankshaft, if instead you want increase the

percentage of balance, the software will indicate you, position

and characteristics of the additional counterweight to use. |

|

|

|

|

The software allows also to see the balance and the

inertia that you obtain using determined counterweights, or

making specifics holes. |

|

|

Shows you the drawing in scale and how change WEIGHT,

BALANCE, and INERTIA with the new counterweights and

holes applied. |

|

|

| ENGINE PERFORMANCE CALCULATION |

The choices of BALANCE and INERTIA in

addition to affect

the forces and the vibrations that you've on the chassis,

affect the engine performance. In fact in function

of the BALANCE that you choose change the forces

acting between piston and cylinder, and on main and crankpin bearings, and therefore on the mechanical friction losses, while the INERTIA affects the

crankshaft speed during the engine cycle, and therefore

modifies the fluid dynamic behavior of the engine, and the relative efficiency.

The software Crankshaft Design is able to calculate the

MECHANICAL LOSSES in function of the choices of BALANCE

that you make, and to see how changes the ENGINE POWER CURVE in function of the crankshaft INERTIA.

|

|

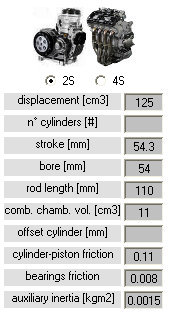

In the software you must enter the main technical

data of the engine, and the power curve detected at

the dynotest. |

|

|

|

|

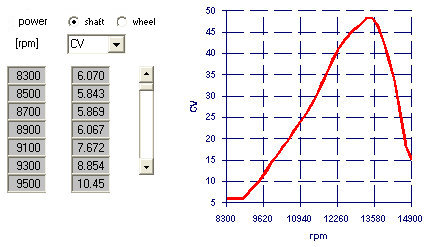

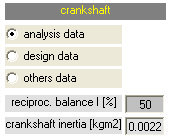

At this point

entering the balance percentage, and the crankshaft

inertia (you can use also the values calculated in

the phases of ANALYSIS, or of DESIGN),

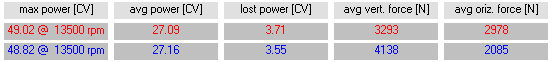

the software will calculate how change the power

curve, the power lost for mechanical friction, and the

forces acting on the chassis. |

|

|

In addition to the global data it also shows the

graphs of all the quantities calculated as a

function of the engine speed. |

|

POWER |

LOST POWER |

| AVERAGE VERTICAL FORCE |

MAX VERTICAL FORCE |

| AVERAGE HORIZONTAL FORCE |

MAX HORIZONTAL FORCE |

|

|

|

This section of the software Crankshaft Design is fundmental

to improve the engine performance in the direction that you want acting on the crankshaft. In fact the

software allows to compare the differents solutions, and therefore to find immediately, that

optimal for your needs. |

|

| Thanks to the software

Crankshaft Design you can therefore study the

interventions to make on the crankshaft as balcance,

and as inertia, to model the power curve for your needs.

You can then work to shift the maximum power peak,

or to have more extension, or to play with inertia

to soften the torque curve, etc., identifying the

optimal solutions quickly and accurately. Moreover

you can always to evaluate how change the forces on the chassis in function of the choices that you make,

managing therefore also eventuals problems related

to the vibrations. |

|

|

| VEHICLE PERFORMANCE CALCULATION |

| In the version PRO of the software Crankshaft Design is

possible to see also how the choices of

BALANCE and INERTIA affect the

vehicle performance.

|

In the software you must enter the features of the

vehicle, of the drive wheels, and of the

transmission. In addition to the main data, the

software also allows you to provide information on

the center of gravity of the vehicle, and on the

grip conditions, so you can also to

simulate the acceleration phase in the real

conditions, taking into account the possibility or not

to use all the available power. In the

software you can also indicate at which engine speed

you want make the upshift gear, so is possible to

evaluate the

vehicle behavior in the real operation

that you want perform. |

|

|

|

At the end of the

calculation the software Crankshaft Design shows the

behavior of the vehicle in all the phase of

acceleration. You can therefore to compare the performance in function of the choices of BALANCE and INERTIA

analyzing the graphs of:

| ENGINE SPEED |

| SPEED |

| ACCELERATION |

and also see the time needed to reach the different speeds, and the speeds

that are reached in the various gears, with the

relative time to reach them. |

|

|

|

|

| As you've seen,

thanks to the software Crankshaft Design, to develop, and to

improve, your crankshaft, becomes really easy, and you can

really increase the performance of your engine, and of your

vehicle, acting also on the crankshaft in the direction of

your needs! Besides are summarized the functionality of the

two versions of the software. |

| |

BASIC |

PRO |

| crankshaft analysis |

X |

X |

| crankshaft design |

X |

X |

| engine performance

calculation |

X |

X |

| vehicle performance

calculation |

|

X |

|

|

|

Purchase |

|

|

|

|

NT-PROJECT - Ferrara (Italy)

- info@ntproject.com |

tutto il

materiale contenuto nel presente sito è coperto dalle leggi sul diritto d'autore ©

2005/19 |

|