|

|

|

|

|

|

|

|

Four Stroke Design

is the ideal tool for technicians and engine tuners to have

quick and precise indications on how to optimize the intake and

exhaust geometries, and the engine valve timing. In fact, in

order to maximize the performance in the desired direction, a

specific sizing is required, and the geometries identified must

match the engine valve timing perfectly, which is why the help

of this software can be fundamental for the best development of

your engine. |

|

|

|

|

|

|

|

|

|

How it works?

|

|

|

|

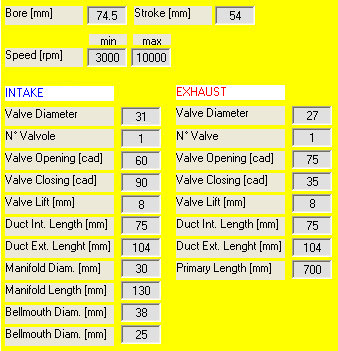

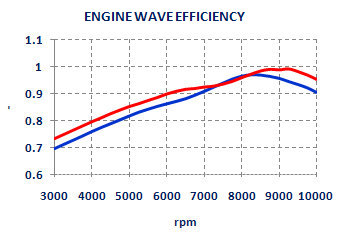

The Four Stroke Design software with the insertion of only the

fundamental data of the engine allows you to analyze the efficiency

of the intake and exhaust geometries, in function of the engine

valve timing, and to quickly calculate the geometries or the valve

timing amelioratives to optimize the performance of the engine in

based on your needs.

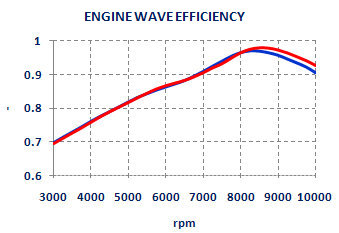

| INTAKE and EXHAUST GEOMETRIES ANALYSIS |

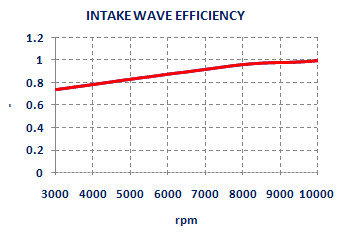

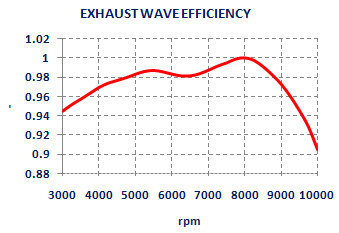

By simply inserting the main dimensions of the current

geometries, and the valve timing of the engine, the software

calculates how the waves pressure generated from the intake

and the exhaust system are effective according to the valve

timing and engine operating speeds.

You can then quickly see for which engine speeds the current

geometries are optimized and whether these are in line with

your performance needs.

|

|

|

|

|

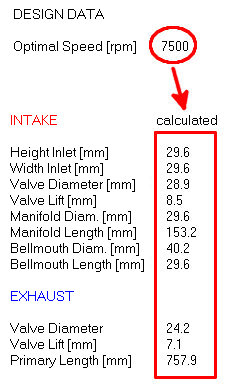

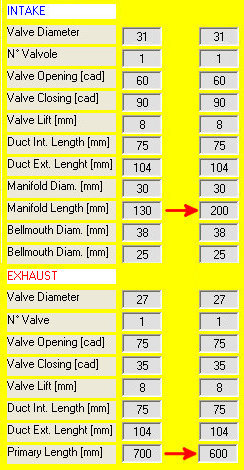

CALCULATION OPTIMAL INTAKE and EXHAUST GEOMETRIES |

Based on the development work that you want to perform and

the performance needs that you want to achieve, the software

calculates the intake and the exhaust geometries that allow

you to maximize the performance in a specific operating

range. In this way it will be easy to work on the geometries

to increase the torque and the power just where you want it.

The software provides a complete sizing:

INTAKE VALVE DIAMETER and MAX LIFT

|

| INTAKE HEAD DUCT DIAMETER |

| INTAKE MANIFOLD DIAMETER and LENGTH |

| INTAKE BELLMOUTH DIAMETER and LENGTH |

| EXHAUST VALVE DIAMETER and MAX LIFT |

| EXHAUST HEAD DUCT DIAMETER |

| EXHAUST MANIFOLD PRIMARY LENGTH |

|

|

|

|

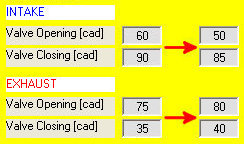

DESIGN OPTIMAL INTAKE and EXHAUST GEOMETRIES |

In addition to the calculated geometries, the software also

allows you to simulate the behavior of other geometries to

find the compromise that best meets your needs throughout

the engine operating range.

The same can be done by keeping the intake and exhaust

geometries fixed, and by evaluating how the behavior of the

engine changes proving different valve timing.

|

|

|

|

|

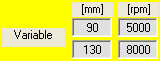

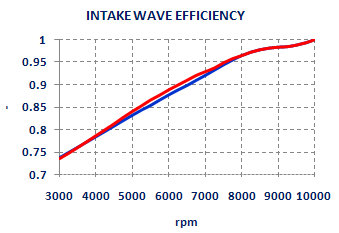

VARIABLE INTAKE GEOMETRY DESIGN |

The software also allows you to study the behavior of

variable intake geometry. In fact, by inserting how the

length varies as the engine speed changes, it shows how the

efficiency of the waves pressure is modified and therefore

the possible advantages that can be obtained.

|

|

|

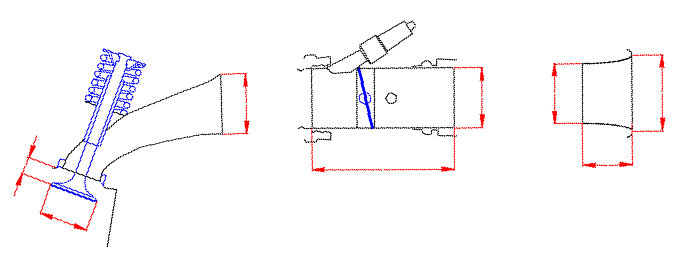

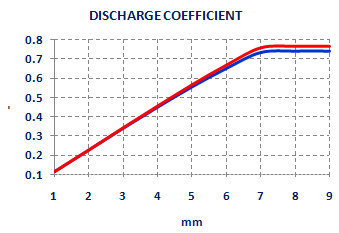

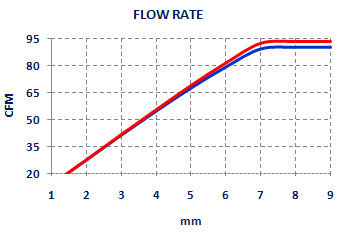

HEAD DUCT GEOMETRY ANALYSIS and DESIGN |

|

In addition to the optimization of the engine waves

pressure, the reduction of the fluid dynamic losses is the

other aspect on which to intervene to maximize the

performance. Usually this work is done only with the help of

experience and with many hours at the flowbench,

unfortunately, however, to reach an improvement solution

often is necessary to proceed by trial with so much waste of

material and with the unknown of not having achieved the

maximum. Thanks to the Four Stroke Design software, it is

possible to quickly analyze the fluid dynamic losses of the

intake head ducts and to simulate the changes that you want

make, seeing before they are even realized if they can be

improved or not. In this way it will be possible to avoid

material waste and immediately orientate the changes in the

correct direction. |

|

|

|

|

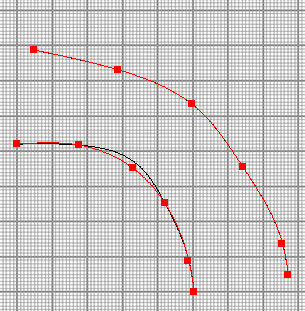

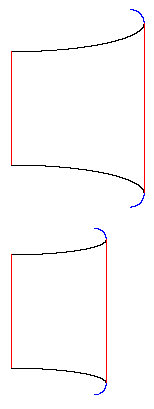

INTAKE BELLMOUTH DESIGN |

The Four Stroke Design software, in addition to calculating

the main dimensions of the intake bellmouth geometry, also

calculates the profile that it must have in order to

minimize the fluid dynamic losses. The software can

therefore be used both to obtain the dimensions of the

intake bellmouth, both to create intake bellmouth of

different sizes which, however, have the optimum profile to

reduce fluid-dynamic losses.

At the end of the calculation the software creates a TXT

file with the coordinates of the profile, and a 2D drawing

in DXF format of the intake bellmouth that can be

manipulated in CAD-CAM systems to proceed directly to the

realization. |

|

|

|

As you have seen from this brief presentation the Four Stroke Design

software is a complete tool that allows to the technician and to the

engine tuners to have all the main indications to proceed with the

development of the engine in the correct direction, thus being able

to quickly maximize the engine performance by intervening on all the

key aspects that influence torque and power. |

|

Purchase |

|

|

|

|

NT-PROJECT - Ferrara (Italy)

- info@ntproject.com |

tutto il

materiale contenuto nel presente sito è coperto dalle leggi sul diritto d'autore ©

2005/19 |

|