|

How it works? |

Today, thanks the carbon fibers

and fiberglass, you can easily to find sheet with various

mechanical properties, the difficulty is to make the correct choice or create

couplings with stiffener that provide the best results in the reed valve

of racing engine for the different conditions of use. The software REED DESIGN was created to satisfy this need and is a fundamental support for those who want to develop kits

of reed petals or want to improve the performance of their reed

valve changing in a timely manner the reed petals.

|

The software contains a database that already included the mechanical properties of sheets of carbon

reed petals most sold (POLINI, MALOSSI, PINASCO, etc.),

and also those used in the racing engine (VORTEX, TM, PAVESI, MAXTER, AKTIVE, ROTAX, etc.). Also, if you have sheets or

reed petals not included in the database that you do not know the mechanical properties,

in the software REED DESIGN there is a form already seen

in the software YOUNG REED for the calculation of Young's

Modulus and of density of reed petals through a simple

instrument diy. |

|

|

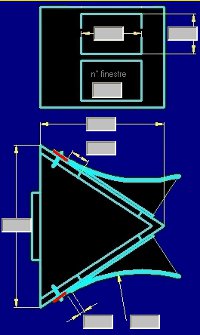

Entering the geometry of the reed valve and choosing the

reed petals and stiffener to apply, the software REED

DESIGN simulate the behavior of the reed petals to vary the pressure difference upstream and downstream of the

reed valve.

|

|

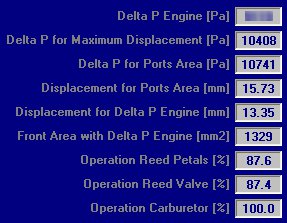

| Moreover entering some data of the engine to which the reed valve

is applied, the software REED DESIGN will indicate the effectiveness of the

reed petals choices, both in terms of performance, both for the

reliability. |

|

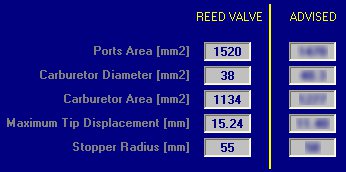

| With the engine data the software provides also some

indications about, port area of reed valve,

diameter of carburetor and stopper radius, that would be more appropriate in relation to engine speed and engine power, so when you are developing the engine

could determine not only the

reed petals more adapted to the reed valve, but also

evaluate changes to the reed valve itself and to the

carburetor used. |

|

Thanks to REED DESIGN you can then:

|

|

to find the reed petals more adapted to your reed

valve and to your engine, to obtain the best performance

in the speed and in the conditions desired; |

|

|

to design solutions with stiffener or with stiffener

and spacer, in order to exploit, in the best way, also the materials

that used only for the reed petals would not be effective for that

reed valve or that engine. |

|

|

to design solutions with stiffener and spacer to

have a variable stiffness that can increase engine efficiency without incurring

in the resonance conditions. |

| |

|

|

|

Click here for a video demonstration |

|

|

Purchase |

|

|

|